Flexible sleeves

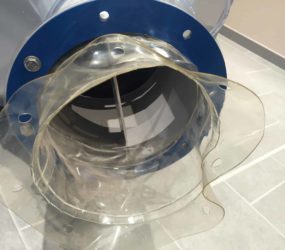

The purpose of a flexible sleeve is to transport a fluid and maintain joint tightness while accommodating expansion, vibration, and alignment differences in all three axes.

The open band sleeve is high temperature resistant and abrasion resistant:

- 2 layers of silicone-coated fiberglass fabric.

- 1 layer of PTFE

- 1 layer needled fleece

- 1 layer of V500 fiberglass fabric

Custom made sleeves for you

In order to meet the needs of its customers, SMV offers a wide range of flexible cuffs made to measure.

Each flexible sleeve manufactured by SMV takes into account all the necessary technical criteria, ie:

- The type of media to be transported: liquids, solids, aggressive media (acids, bases, solvents or abrasives), powders, water vapors, hydrocarbons, etc.

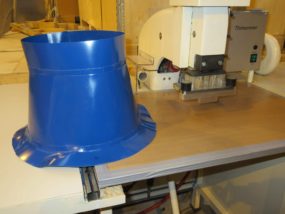

- The geometry of your equipment: square, round, conical, square-round, oval sleeves, equipment requiring a sleeve with smooth or sloping edges (with or without a hole) or an eccentric sleeve.

- The operating temperature and pressure or vacuum.

- The environment: outdoor or indoor installation, nearby influencing factors to be considered (splashes, etc.).

- The application: Industrial transfer, marine, nuclear, furnaces, chemical industry, petroleum industry, electronics, pharmaceutical, medical.

- Applicable certifications or regulations: Need to comply with certain food standards, ATEX.